Old tyres are finding a new use thanks to a family-owned Victorian company which is now recycling them into products that make pathways, schools, sporting surfaces and community spaces safer.

The Coloured Recycle Group (CRG) have been making non-slip surfaces for more than 60 years. Initially using sand in the 60s, CRG has now developed a more sustainable and high-performing product using technology to recycle Australia’s used tyres into a non-slip surface.

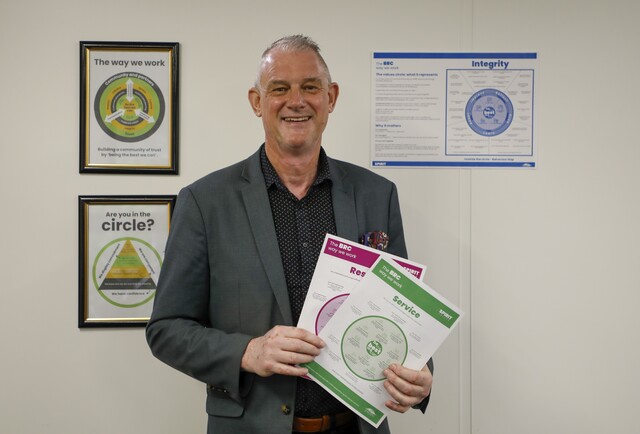

Vincent Caddy’s father started the coating business in 1962 and 60 years later the business, which now includes a third generation of the family, is not only creating high-quality non-slip surfaces but also using recycled materials to increase the sustainability of their products.

CRG, is making non-slip surfaces using a rubber crumb from Australia’s used tyres. Vincent explains their Safe T Rubber coat can be applied to almost any building surface including concrete, asphalt, timber, metal, brick pavers and metal.

This makes it a highly versatile product and used in applications like pool surrounds, sporting surfaces, pathways, walkways, wet areas, workshops, and kitchens. And the fact that it comes in a range of colours is a real bonus.

Albion Primary School recently put Safe-T rubber coat to the test when it refurbished its basketball court. The results were a great looking basketball court that was safer to play on compared to the original bitumen court.

Marita, Albion Primary School’s Physical Education teacher, commented: “The surface not only looks good but feels fantastic underfoot. Students are able to stop and pivot without slipping, it is the perfect surface for netball or basketball.”

Marita felt the new surface also made it safer for the children playing on it, “if students do fall over the grazes are minimal compared to those happening on the old bitumen surface”.

The CRG rubber-non-slip surface is just one of the many Australian initiatives and products promoted by Tyre Stewardship Australia (TSA). TSA’s vision is for a circular economy for Australia’s used tyres and works to raise awareness of the value of tyre-derived materials and support opportunities for Australia to use products made from used tyres.

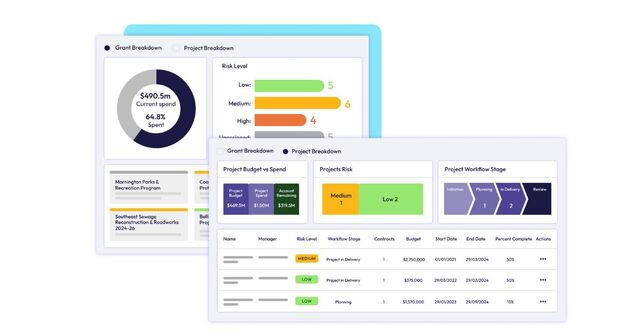

TSA CEO Lina Goodman says: “Each year almost 500,000 tyres reach the end of their life in Australia, this provides an opportunity for Australia to recover the valuable materials of our used tyres, making them available for Australian manufacturing, to become products that the Australian market can invest in and benefit from while supporting Australia’s circular economy.”

TSA has invested over $9 million into projects that innovate and increase the use of Australian tyre-derived materials. Rubber crumb in roads, permeable pavements, and sporting surfaces are all products that use tyre-derived materials and allow Australia to continue to derive benefits from our valuable resources by keeping them in the economy for longer.

Lina explains: “We’re losing out if we’re not prioritising products with end-of-life tyres in them. There are a raft of products that Local Governments can use in roads, parks and community facilities that can help them achieve their ESG goals, claim potential greenhouse gas emissions savings, and realising the benefits of the resources in old tyres creating higher performing products.”

Companies like Coloured Recycle Group recognise the benefits of recycled tyre-derived materials while remaining competitive with conventional products.

“We’ve always been in the coating business. My father started it up in 1962. We were coating with the sand that they used for making casting in the 60s, 70s and 80s and 90s. But in the 70s there were 4000 foundries in Australia making castings and today there are only six. All the castings were eventually moved overseas -throughout Asia. I am proud to say we are still operating out of Victoria,” said Vincent.

Needing to diversify, Vincent’s daughter’s suggested in 2003 that they use recycled glass bottles in bicycle and bus lanes. Building on that success, the company decided to look into using rubber from Australian recycled tyres. After about three years of research and development, Safe T Rubber colour coating was ready for market.

“I think we are the only people in the world who can colour coat down to 0.2 of a millimetre,” Vincent said.

“It’s only been in the past 12 months where we’ve been able to see how the Safe T Rubber is ticking all the boxes on ‘real world’ longevity, wear and tear and that sort of thing.

“And we only use Australian recycled tyres in the process, both in the binder, and is 100 per cent of the aggregate component of the product.

“It’s just the beginning as far as the rubber goes. Brisbane has something like 520km of bike lanes and walkways that they want us to help get ready for the Olympics. So, in conjunction with a partner company operating out of Brisbane, we have some trials underway and we are expecting excellent results.”

According to Vincent there are distinct advantages to using the rubber coating particularly when it comes to the weather.

“We found here in Victoria when we get hot days, though we don’t get many, you can’t walk on the concrete but the rubber doesn’t get as hot. The same in the cold it doesn’t get cold because rubber is such a great insulator.”

If you want to know more about how CRG’s Rubber Safe T coat could refurbish or create a new safer surface for your next project, get in touch with Vincent on 1800 223 274 to chat about a surface solution. And if you want to investigate other tyre derived product for your LGA , drop us a line at Getonboard@tyrestewardship.org.au