Waratah-Wynyard Council, like many other councils, is looking to the future to ensure its ongoing sustainability. With external funding sources often unreliable, the General Manager and Executive Management Team decided that it was time to really focus on ensuring that it was making changes internally to make the council efficient and effective to provide best value to the community.

While there are several major projects occurring to make this happen, one of the key underlying foundations to driving the required cultural change is the introduction of ‘LEAN’ practices and tools into the organisation.

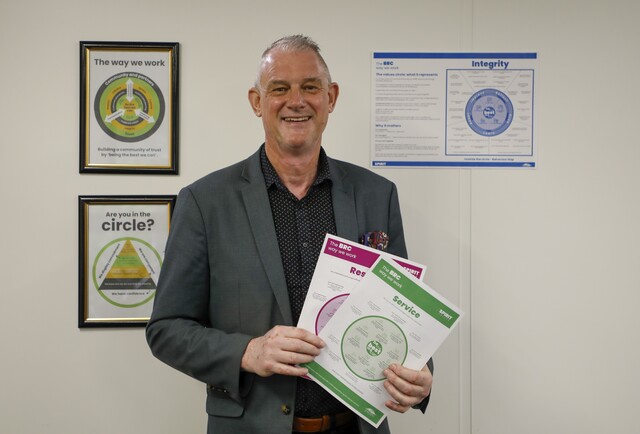

Along with our resource-sharing partner, Circular Head Council, we have engaged Tasmanian firm Productivity Improvers to deliver LEAN training to both organisations.

The adoption of LEAN principles across the Council will ensure that we are focusing on utilising the knowledge and expertise of our employees in making improvements that make us more efficient and cost effective by using a standard framework of tools to make smart decisions.

LEAN tools are helping us to start to introduce a cultural change where we look for the best way to do the job and question the status quo so that we don’t just continue to do things “because it’s always been done that way”.

We are still in the early days of implementation and embedding the tools into our standard processes. Our initial focus has been on priority opportunities for our Executive Managers (to drive the change) and then our outdoor workforce coordinators to undertake training as there were some obvious quick wins that were identified.

To date 33 staff has taken part in LEAN training; including a group of six outdoor staff who are the first group of staff to do the Cert IV in Competitive Systems and Practices. As part of the Cert IV course each participant had to select a work project and take what they had learnt and apply it in a practical sense.

This resulted in six projects that had an immediate impact on productivity and efficiency including the complete redesign and eventual manufacture of a new trailer at the Works and Services Depot for the Urban Works team.

Project leader Urban Works Coordinator Paul Whitsitt said the new trailer was designed to help ensure the team had easy and better access to the right tools and equipment on site when needed.

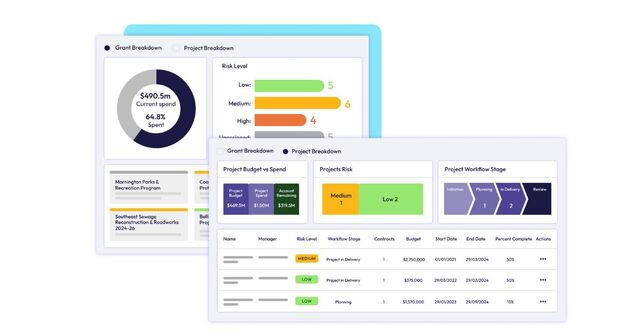

Calculations on lost time and kilometres travelled per day were completed and found there was a lot of time over a year that we could save. Based on the calculations it was identified that more than 105 hours and 3172km per year were lost because of the existing trailer and how it was being used. It was clearly identified during the review that staff often needed to return to the depot to get additional equipment, whereas with the new design everything they need is right there on site.

The new design means that approximately $6700 per year will be saved and there is the added bonus of the improved safety and ergonomic design of the trailer, which means that there is less chance of injury to our staff. The estimated time to achieve a return on investment of costs involved in the project is 16 months.

Each of the projects implemented so far have had similar results and that doesn’t include the intangible results of staff seeing the action being taken to improve the way things are done and the fact that good ideas lead to more good ideas. Hopefully in the near future the only issue will be ‘what good idea do we work on first?’