Millions of waste tyres could soon be headed for a new life not on, but as part of Australia’s road infrastructure.

The new national specifications for Crumbed Rubber Modified (CRM) asphalt were achieved through the work of Australian Asphalt Pavement Association (AAPA), Tyre Stewardship Australia (TSA), with the assistance from Transport and Main Roads Queensland, Main Roads Western Australia, Sustainability Victoria and the Australian Road Research Board.

The specifications were developed using vast amounts of research and development data to achieve cohesive national standards, for use across the country.

The document was published by the AAPA national technology and leadership committee to facilitate the construction of demonstration trials of CRM gap graded asphalt (GGA), as well as to promote the wider use of CRM open graded asphalt (OGA) in Australia.

The crumb rubber modified binder technology in the specification is based on the technology used in California and Arizona.

The CRM OGA mix design process in this specification has been validated through demonstration trials in Queensland, now with the first demonstration section of CRM GGA placed at the Gold Coast on June 28.

The new national specifications for both OGA and GGA applications, and for crumbed rubber spray seal, could eventually see nearly 10 percent of the accessible feedstock for tyre-derived crumb rubber produced in Australia consumed in domestic road manufacturing. That equates to the consumption of nearly 4 million end-of life tyres per year.

The benefits of using both CRM asphalt and spray seal have been known for some time, particularly for rubberised spray seal, given it has been in wide use across some state’s rural and regional highways for decades.

CRM asphalt can offer better drainage, reduced noise, improved rut and crack resistance and reduced maintenance cycles, whilst rubberised spray seal has delivered superior durability, better drainage and noise reduction.

Now the national specification for both CRM asphalt types and spray seal will allow engineers and roads contractors to work within known parameters to deliver the benefits such products can offer.

Supporting the national specifications, TSA and AAPA will be delivering a series of tech-talks to state and local authority roads bodies, roads engineers and contractors. All with the aim of increasing understanding of the application of the products.

According to TSA Market Development Manager, Liam O’Keefe; “Reaching a national standard has been a critical part of increasing the potential market for crumb rubber use in Australian roads.”

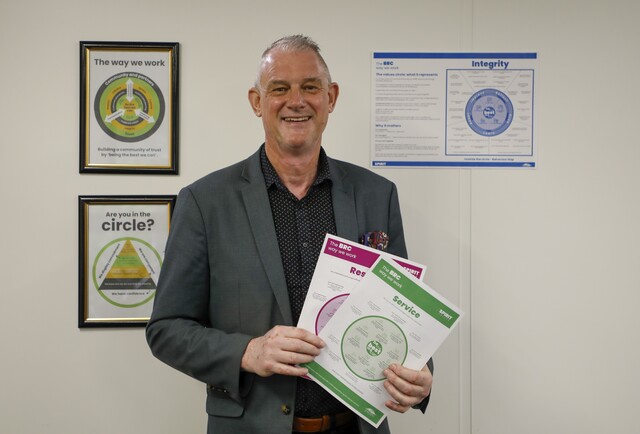

Erik Denneman, Director of Technology and Leadership at AAPA was also enthusiastic about the new specifications. “This is another great outcome from the close collaboration between industry and road agencies in Australia. For AAPA this initiative fits our objective of encouraging the efficient use of available resources and promoting the use of sustainable products.”

Formalising national CR modified asphalt specifications along with increasing both CRM asphalt and spray seal utilisation has been a significant objective for TSA and collaborating agencies.

With Australian population growth driving road infrastructure demands, initiatives such as the new CRM asphalt specifications are integral to addressing a waste problem with a circular economic approach, delivering both practical and environmental benefits.

The new national specifications can be found on the AAPA and TSA websites:

aapa.asn.au/aapa-national-model-specifications/

tyrestewardship.org.au/tsa-knowledge/national-specifications-for-crumb-rubber-roads

*Copy supplied by TyreStewardship